Fabric inspection machines are used to inspect fabric materials in order to find manufacturing defects(weave), mechanical defects (holes) and dirty spots. For convenience of operator inspection machines have an illuminated panel, under the material.

Spreading is the process of unwinding large rolls of fabric into long, wide tables in preparation for cutting each piece of a garment. The number of layers of fabric is dictated by the number of garments desired and the fabric thickness.

Automatic fabric spreading means the smooth laying out of various types of fabric according to specific length.

We have been counted amongst the most trusted names in this domain, engaged in offering a standard quality range of End Cutter Machine to our clients.

Offered End Cutter Machine has sturdy construction and timely delivered by us to our clients.

Features:

Energy efficient

Less maintenance

Hassle free working

A power tool used for cutting cloth. Very similar in operation to a band saw. it has an endless loop blade and the material to be cut is supported by a flat table. They have fine blades that rotate through a slot in the cutting table while cutting.The operator positions ,controls,and guides the fabric block around the knife.

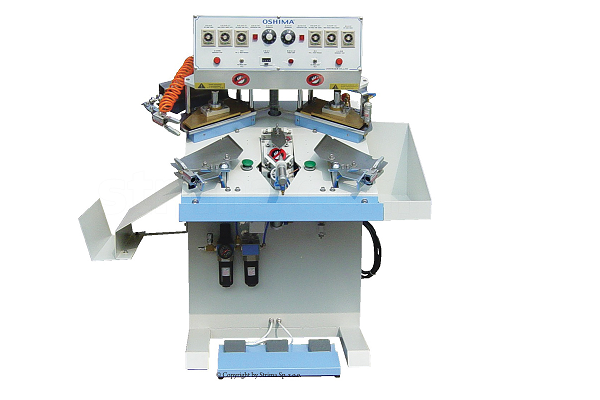

Fusing Machines are used in the garment industry to fuse a material capable of being fused to a base fabric through the process of pressure, heat, and time. The fused material should have acceptable strength, the ability to stand continuous wash, or any fabric treatment.

A heat press is a machine engineered to imprint a design or graphic on a substrate, such as a t-shirt, with the application of heat and pressure for a preset time period. While heat presses are often used to apply designs to fabrics, specially designed presses can also be used to imprint designs on mugs, plates, jigsaw puzzles, caps, and other products.

Electricity or an electromagnetic charge is sent through the coils to the ground and back to the coils. Metallic objects interrupt the signal, which results in the unit creating an audible sound. This type of needle detector machine is fitted with a microprocessor which enhances the detecting ability.

An indispensable tool for any dry cleaning is a spotting machine, which is used to easily remove stains from clothing with steam and stain removers. Spotting machines are ideal for cleaning spots and small areas quickly, without having to set up a larger machine. It is extensively used by the professional cleaner, contract cleaner, domestic cleaner and for in- house spot cleaning.

LARGE FLAT TOP padded with Imported Silicon padding, Strong welded construction, Thermostatically controlled stainless steel table heater, Extended exhaust duct with lighting device, Adjustable garment hanger stand, Garment storage rack. POWERFUL SUCTION through centrifugal blower activated by spring loaded full length foot pedal working in conjunction with sturdy micro switch, Ideal cover material helps achieve excellent ironing results.

Stiromax fully automatic Steam Generator successfully produces steam in a regulated, efficient, and a safe manner. It is extremely user friendly and efficient machine due to its automatic pressure controller, automated water supply and multiple in built protection devices. The Electric Steam Generator offered by us is made up of optimum quality material that ensures high durability and exhibition of unbeatable performance.

We supply steam irons suitable for all types of clothes. All items are imported from italy.

Thread-sucking machine absorbs all the loosley-attached threads stuck on the garment after stitching.

The average daily capacity in an 8-hour shift is 2000 pieces, whereas if this operation is done manually, it would require 4 people and 24 hours to do the same.

The accumulated loose threads inside the machine can be removed by simply opening the front door.

Thread trimming is one of the common processes in industrial apparel manufacturing. Cutting threads from stitched garments prior to garment finishing is a non-value added but unavoidable process. Number of helpers are hired for thread trimming job in garment factories. Manual thread trimming is time consuming and all trimmed threads can't be removed permanently from garments.

Various types of collars are available.

At One time, cutting, turning and press can be adjusted and exchange knife blade angles

Easy to operate & high productivity

Various types of cuffs are available.

At One time, four cuffs can be turned and pressed

Easy to operate and gives high productivity

Suitable for pressing topper & legger.

Scissor action designed for smart operation.

Different pressing mode such as gentle pressing and heavily pressing can be selected according to various fabrics.

With up and down steam spraying and heat preservation design, the lower buck could vacuum.

PONY's form finisher’s range MG has been engineered to meet the demand of blow finish for all outer wears in dry cleaning and laundry stores, the garment industry, ironing services and in the hospitality industry.

Finishing cycles controlled by microprocessor with 10 stored programs, manual cycle start or automatic cycle start using a foot pedal, adjustable hot air flow, revolving or fixed dummy if combined with the sleeve tensioning group.

The cone winding machine is mainly used for rewinding the bobbin into a cylindrical or conical bobbin after being unwound. The sizing machine is mainly used for fabric sizing. The carding machine is mainly used for pure spinning and blending of wool and chemical fiber. The raw hair is mixed in a certain proportion, and after several rounds of combing, the drafting is processed into a compliant bristles for the roving machine to produce the roving.

As the name suggests, a garment steamer is an appliance that uses water as an input to create moistness or steam to perform its functions. It comes with an inbuilt tank that it uses to store the water. Its primary purpose is to clear up all the wrinkles and creases in your clothes.

Fabcare ‘Washing Machines’ are designed for all types of laundry Jobs, technical and enzyme washing. Machines are available with different types and size to cater the need of different Fabrics such as Denim, Cotton, Rayon, Knitted,Woolen garments

Available Sizes 15 to 28, Kg. Dry weight per charge capacity.

Etiam porta sem malesuada magna mollis euismod. Vivamus sagittis lacus vel augue laoreet rutrum faucibus dolor auctor. Maecenas faucibus mollis interdum. Donec id elit non mi porta gravida at eget metus. Aenean lacinia. Donec ullamcorper nulla non metus auctor fringilla.

FABCARE Washers use up to 70% less water, 50% less energy, and approximately 50% less chemicals-enzyme, and delivers superior cleaning results compared to conventional washing machines.

Especially Designed Drum mechanically pressurized liquor to be penetrated into the garments. Said system provides 50 % more loading allowance along with 70 % saving from water, chemicals, heating energy, waste water, 40 % saving from electricity and 50 % saving from dye stuff. The result is higher quality, easier operation, more economic and competitive dyeing without any rejection even during the long process time.

Especially designed for laundries where quality of the process, energy and water saving are a priority. Fabcare high spin Hydro Extractor offers a top performance to meet the needs of most demanding customers. The user friendly and intuitive programming is suitable for all types of laundries, dry cleaners, self service, commercial laundries, hospitals and care homes. It is available in various sizes depending on the specification of the customer.

Industrial dryers are used in industrial processing applications to eliminate or remove moisture, water and other solvents from the material under processing. The extensive range by Fabcare offers a choice of single and double dryers with a filling weight ranging from 10 kg to 240 kg. Optional special features include complete Stainless Steel body with steam spray, cool down feature, humidity control meter, residual moisture control and fire suppression system.

New FABCARE SPLASH washing machine is able to useless water and deliver a gentler wash, thanks to the revolutionary SPLASH technology, helping LAUNDRY-DYEING units to save on average almost a million liters of water each year.

Available Sizes 6 to 600 Kg. Dry weight per charge capacity.

This machines are specially designed to make various processing operations on ready-to-wear garments. In order to get these effects, we use a spray-based system with chemical products and pigment-based colors. Each machine comes with a suction system, the water barrier and filtering system is a standard feature. It is fitted with dummies that can be inflated and deflated automatically and with a pneumatically-controlled 180c rotation device.

We have boiler heaters, sensors, fusing machine belt cleaning spray, fusing machine rivets, Blue foam for tables, solenoid valves, hose pipes and much more in ready stock

Etiam porta sem malesuada magna mollis euismod. Vivamus sagittis lacus vel augue laoreet rutrum faucibus dolor auctor.

©2022. AFM Group. All Rights Reserved.

Website Developed by Infinity Codio